APPLICATION

The extruder produces extended products from plastics: pipes, profiles, plates, films, or large-volume products.

It is used for the production of:

- Engineering pipes (polypropylene, polyethylene, PVC)

- PVC profiles for windows and doors

- Panels/plates for window sills and doors

- Diffusers for lamps (polycarbonate/plexiglass)

- Cable channels, baseboards

- Edge tape

- Cable sheath

- PVC seals

- Hoses

- Medical tubes

- Decorative frames

- Grids

- Wood-plastic composites

- PVC composites

FEATURES

The components and mechanisms of the extruder are reliable and have a simple design. Malfunctions are rare and easily fixed. The equipment requires a low maintenance cost.

There are several key parameters that need to be controlled in the extruder operation. The operator and 1-2 auxiliary workers are required to start and operate the machine.

Forming dies of extrusion machines have lower metal consumption, compared to the molds of injection molding machines.

Types of extruders:

- Single-screw

- Twin-screw

Single screw extruder is the simplest type of machine and is used for processing plastics with good mechanical characteristics.

When processing powders and raw materials that tend to stick together, the raw material in the single-screw extruder circulates unevenly. It can cause overheating of plastic or pressure surges on the die.

Twin-screw extruder provides a more uniform circulation and melting of the material in the cylinder. Rotation of the screws can be parallel or counter. Twin-screw machines are recommended for processing hard-to-loose plastics.

The single-screw mechanism only cleans the cylinder. Twin-screw extruders can be completely self-cleaning.

The extruder type and performance are selected individually depending on the production task. Dies for extruders are made to order according to product drawings. They determine the shape of the finished product.

STRUCTURE AND OPERATION

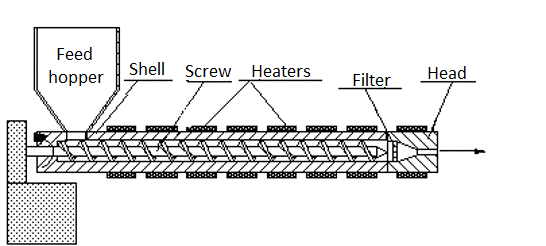

The main mechanism of the extruder is a screw. The force that rotates the screw is transmitted from the electric motor through the gearbox. The motor is controlled by a frequency controller.

The plastic raw material is fed through the feed hopper to the screw feed area. The necessary additives and dyes are pre-added to the mixture. Optionally, a granulator can be used.

As moving along the heaters in the plasticization zone, the polymer melts and is fed by the screw to the extrusion head. The extruder builds a pressure of 15-100MPa. The molten polymer is forced through the die heads. The die pattern determines the shape of the products.

After exiting the extruder, the polymer is cooled and cured in the air or in a bath. Plastic achieves the required shape and mechanical properties. During extrusion, the chemical composition of the plastic does not change.

The equipment operates continuously. Therefore, winding or cutting the finished product must be provided.

PRODUCT LINE

| EMD-55 | EMD-65 | EMD-90 | EMD-110 | EMD-130 | ||

| Screw length/diameter | 25 / 28 | 25 / 28 | 25 / 28 | 22 | 22 | |

| Screw diameter (mm) | 55х2 | 65х2 | 90х2 | 110х2 | 130х2 | |

| Rotation speed (rpm) | 60 | 60 | 44 | 38 | 30 | |

| Engine power (HP) | 20 | — / 30 | 60 / 75 | 90 / 100 | 125 / 150 | |

| Cylinder heater power (kW) | 18 | — / 22 | 30 / 38 | 42 / 50 | 80 / 90 | |

| Flange heater power (kW) | 4 | 5 | 6 | 7.5 | 8.5 | |

| Cylinder cooler power (kW) | 0.6 | 0.6 | 0.6 | 1.2 | 1.2 | |

| Plant capacity (kW) | 38 / 53 | 40 / 51 | 82 / 102 | 119 / 133 | 175 / 192 | |

| Number of mold heaters | 2+3 | 2+3 | 2+4 | 2+4 | 2+4 | |

| Number of cylinder heaters | 4 | 4 | 4 | 4 | 5 | |

| Hopper capacity (kg) | 75 | 100 | 150 | 200 | 200 | |

| Height (mm) | 1100 | 1100 | 1100 | 1100 | 1100 | |

| Weight (kg) | 1600 | 2000 | 3000 | 4100 | 5600 | |

| Capacity (kg/h) | High density PE | — | — | — | — | — |

| Soft PVC | — | — | — | — | — | |

| Hard PVC | 60 / 80 | 120 / 160 | 400 / 500 | 600 / 700 | 800 / 1000 | |

| EMD-55C | EMD-65C | EMD-80C | EMD-92C | ||

| Screw length/diameter | 22 | 22 | 22 | 22 | |

| Screw diameter (mm) | 55/112 | 65/132 | 80/156 | 92/188 | |

| Rotation speed (rpm) | 40 | 40 | 40 | 40 | |

| Engine power (HP) | 30 | 50 | 75 | 150 | |

| Cylinder heater power (kW) | 16 | 22 | 39 | 53 | |

| Flange heater power (kW) | 2 | 4 | 4 | 8 | |

| Cylinder cooler power (kW) | 1.5 | 1.5 | 1.5 | 2 | |

| Plant capacity (kW) | 48 | 67 | 102 | 160 | |

| Number of mold heaters | 2 | 4 | 8 | 10 | |

| Number of cylinder heaters | 4 | 4 | 4 | 4 | |

| Hopper capacity (kg) | 75 | 100 | 150 | 150 | |

| Height (mm) | 1100 | 1100 | 1100 | 1100 | |

| Weight (kg) | 2300 | 3600 | 3900 | 4800 | |

| Capacity (kg/h) | High density PE | — | — | — | — |

| Soft PVC

|

— | — | — | — | |

| Hard PVC | 60-120 | 80-150 | 250-360 | 450-600 | |

| EMS-45 | EMS-55 | EMS-65 | EMS-85 | EMS-100 | EMS-125 | EMS-150 | ||

| Screw length/diameter | 24 / 28 | 24 / 28 | 24 / 28 | 24 / 28 | 24 / 28 | 24 | 24 | |

| Screw diameter (mm) | 45 | 55 | 65 | 85 | 100 | 125 | 150 | |

| Rotation speed (rpm) | 60 / 120 | 60 / 120 | 60 / 120 | 50 / 120 | 50 / 120 | 50 | 45 | |

| Engine power (HP) | 15 / 30 | 20 / 30 | 30 / 75 | 40 / 150 | 50 / 200 | 100 | 125 | |

| Cylinder heater power (kW) | 7.5 | 10 | 12 | 14 | 15 | 20 | 25 | |

| Flange heater power (kW) | 0.5 | 0.6 | 0.7 | 1 | 1 | 1.5 | 2 | |

| Cylinder cooler power (kW) | 0.05х3 | 0.05х3 | 0.05х3 | 0.1х3 | 0.1х4 | 0.2х3 | 0.2х3 | |

| Plant capacity (kW) | 22 / 34 | 30 / 68 | 36 / 92 | 47 / 160 | 88 / 238 | 133 | 180 | |

| Number of mold heaters | 2 | 3 | 3 | 3 | 4 | 5 | 6 | |

| Number of cylinder heaters | 3 | 3 | 3 | 4 | 5 | 7 | 8 | |

| Hopper capacity (kg) | 50 | 50 | 50 | 100 | 100 | 150 | 150 | |

| Height (mm) | 1100 | 1100 | 1100 | 1100 | 1100 | 1100 | 1100 | |

| Weight (kg) | 850 | 950 | 1100 | 1600 | 2200 | 2500 | 3000 | |

| Capacity (kg/h) | PE pipes | — / 100 | — / 70 | — / 150 | — / 350 | — / 500 | — | — |

| PE profile | 40 / — | 25 / — | 70 / — | 100 / — | 150 / — | 200 | 250 | |

OPTIONS

An extruder with special equipment for preparing raw materials and processing finished products forms a production line.

Additionally can be supplied:

- Raw material preparation and loading system (drying, calibration)

- Mixers (mixing raw materials for co-extrusion and composite production)

- Degassing unit (prevents the formation of cavities in the product due to bubbles in the molten plastic)

- Air and liquid coolers (for forced cooling and acceleration of polymerization)

- Profile pulling mechanisms

- Cutting machine

- Stacker

- Winding machine

- Marking systems

- Printers and laminators

SELECTION

To select a suitable model of the tangential fan, please, leave a request to our specialist. In the request, describe the task that you need to solve.