APPLICATION

Soldering is a widely used method for installing cooling systems and gas/liquid transport systems assembled of copper pipes. A special type of solder must be used for reliable soldering of pipes and fittings.

Solder is filled into the mounting gap and heated with a burner until it melts. If the technology is strictly followed, a wide soldering belt is formed, which guarantees the connection tightness. The joints withstand tensile tests without breaking and are stronger elements than the copper pipes themselves.

The strength and corrosion resistance of the joint depends on the correct choice of the solder.

FEATURES

Depending on the purpose of communications and the operation temperature (-50..250°C) of copper pipes, the following types of solder are used:

- Low-melting (soft) solder is used for pipelines for drinking and hot/cold water supply and heating with an operating temperature of up to 110°C

- Refractory (hard) solder features higher temperature resistance and shear resistance and is used in heating systems

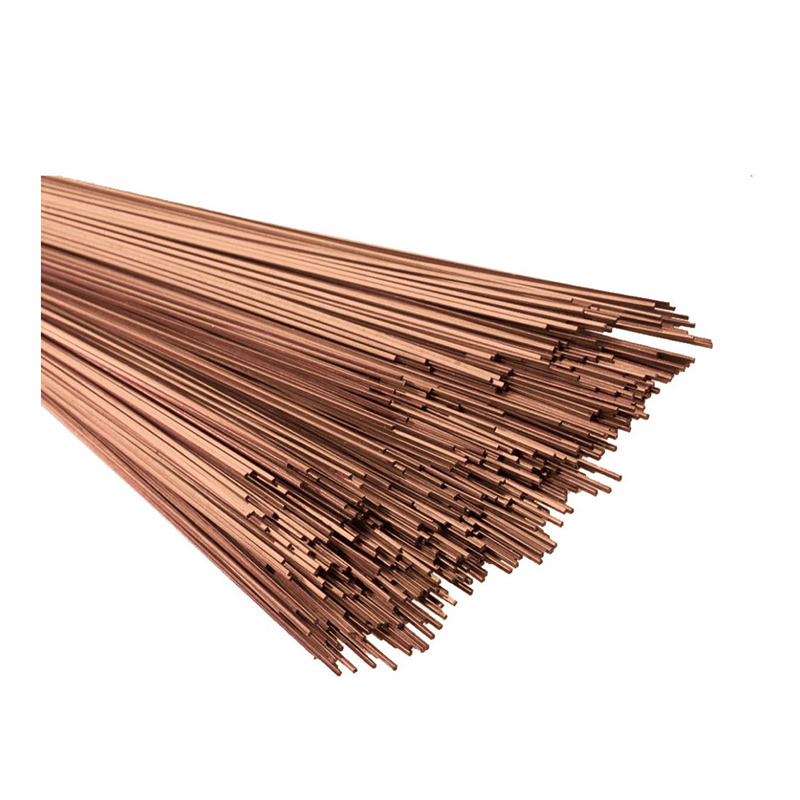

The solder is a tetrahedral rod with a length of 500mm and a cross section 1,5 / 2 / 3mm. The bars are packed in boxes of 1.0 kg. The minimum package contains 25 boxes.

The solder can also be supplied in the form of rings

- Copper solder is recommended for soldering with a gap of 0.5-1.5mm

- Silver content: 0, 2, 5, 15%

- Phosphorus content: 5-7%

- Strip size: 1x30x500mm

- Number of pieces per pack: 28

SELECTION

To select suitable grades of copper solder, please, leave a request to our specialist.