APPLICATION

Heating and maintaining the set temperature, anti-condensation and anti-icing.

Due to elasticity and small thickness, the heaters are suitable for heating non-standard shaped surfaces where rigid heating elements are not applicable.

Silicone heaters are suitable for the heating of:

- Evaporators

- Defrosting systems for heat exchangers

- De-icing ventilation systems

- Molds and equipment

- Metal drums, IBC, and containers

- Packaging machines

- Hydraulic equipment

- Batteries

- Aircraft engines

- Sterilizers, incubators, blood analyzers

- Catering equipment

- Laboratory equipment

- Cosmetology equipment

- Floors

FEATURES

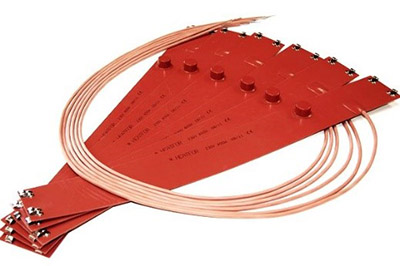

Silicone heaters are easily attached to surfaces and provide uniform heat transfer.

Standard-sized heaters are manufactured for typical applications. The heater power and operating voltage can vary according to the customer’s specifications.

We manufacture heaters of the required geometry. The template for the conduit etching is set by the CAD file.

The heaters can be operated for a long time under the exposure to atmospheric factors and some chemicals. The materials are environmentally friendly and do not emit harmful substances during operation

Specification

- Specific power: 0.02-3.0 W/cm2

- Operating voltage: 1-400V

- Operating temperature: -50..200⁰C (briefly 260⁰C)

- Thermal conductivity at 100⁰C: 15×104W/cm*K

- Dielectric strength: 12kV/mm

- Thickness: 0.8-3.0mm

- Width: 20-600mm

- Length: 20-2800mm

- Minimum bending radius: 50mm

- Ingress protection: IP65

- Resistant to alcohols, medium-strength acids (formic, acetic, up to 10% hydrochloric and sulfuric), brake fluid and oils, detergents, acetone, solvents

STRUCTURE AND OPERATION

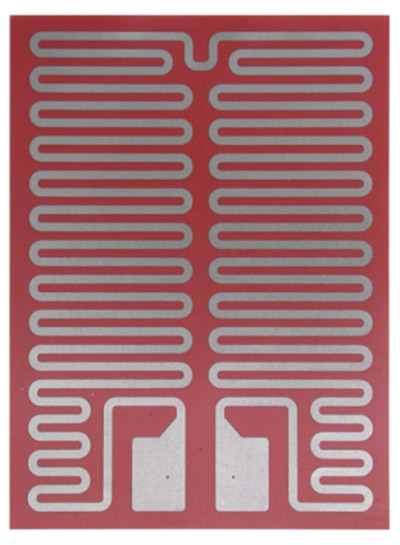

The heater is manufactured on the base of etched nickel alloy foil. This technology enables to produce elements of the required shape with the required electrical characteristics. For example, high power elements with a double loop.

The conductive element is hermetically packed in a silicone sheath. The material and type of contact wire insulation depends on the task and can be single/double-layer, Teflon/silicone. The end section is vulcanized.

Due to thermally stable silicone, the heaters can be used at temperatures of up to 200°C. The product thickness can be varied from 0.8 to 1mm. Polyester (110°C, 0.20-0.25mm) or polyimide (260°C, 0.10-0.15mm) can be used as sheath materials.

The temperature is set and controlled using the built-in thermostat or an external controller with a Pt100 sensor or a thermocouple.

Flexible heaters are mounted on a self-adhesive layer. The joint has good adhesion to stainless steel and plastics. The installation method is applicable up to 100⁰C.

For high-temperature applications (up to 200 °C), the silicone heater is attached with a one-or two-component vulcanizing adhesive.

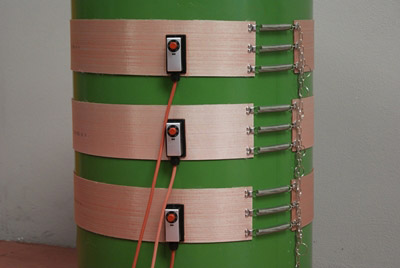

Barrel heating belts are mounted with pressure springs. The flexible heater is securely fixed to the barrel. Easy removal and mounting.

PRODUCT LINE

- Length: 20-2800mm

- Width: 20-600mm

- Specific power: 0.02-3W/cm2

- Т: -50°C..200°C

- Length: 300-2500mm

- Width: 20-580mm

- Specific power: 0.01-3W/cm2

- T: -50°C..180°C

SELECTION

To select a suitable model of flexible silicone heater, please, leave a request to our specialist. Describe the task you need to solve.