APPLICATION

The nozzle is necessary for the plasma jet formation. The profiled channel compresses the plasma and directs its flow to the workpiece. The higher the plasma flow rate, the higher the cutting speed and edge quality.

The consumable tool is used in manual and automated cutting equipment. Plasma cutting of metal is used in mechanical engineering and shipbuilding, oil and gas industry, production of metal structures

The electrodes are suitable for plasma cutting equipment of the following types:

- Mechanized and manual

- Vertical and oblique cutting

- Low-carbon and stainless steel, aluminum

- Marking

The quality of the plasma cutting nozzle affects the cutting accuracy, edge evenness, and overall performance of the equipment.

The plasma cutter nozzle wears out during operation. The wear is caused by insufficient cleanliness or dryness of the gases used and exposure of the nozzle surface to metal melt. The opening diameter increases and the edge smoothness deteriorates. As a result, the cutting speed decreases and the cutting quality deteriorates.

The nozzle must be regularly checked and replaced if signs of degradation are detected.

The range includes all the necessary plasma tools: electrodes, nozzles, bushings, screens, protective caps, swirlers.

FEATURES

Nozzles for plasma cutters are made of standard quality. To extend the service life, components must be correctly selected depending on the operating current, the metal thickness, and the alloy grade.

The nozzle has a conical shape, which forms and directs the plasma jet. The nozzle surface is smooth, the opening has no roughness.

The nozzle diameter determines the gas flow rate. The larger the diameter, the more intense the cutting. Standard cutting diameters are 1.0, 1.1, 1.2mm. The nozzle length is 9-12mm.

The nozzle body is finely threaded to seal the chamber in which the plasma is generated. Tight sealing reduces the leakage of gas converted into a plasma jet.

The nozzle is easily mounted on the plasma cutting device. During operation, regular checks and replacement are required if the color changes or defects appear.

STRUCTURE AND OPERATION

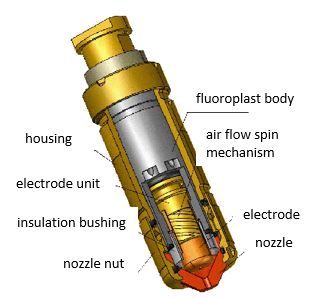

The cutter of plasma cutting device consists of an electrode unit and a nozzle separated by an insulating bushing. The screen protects the plasmatron interior from melt drops.

The electrode consists of two parts: the housing and the insert. The housing serves as a current conductor and heat sink. The insert is made of a refractory metal (tungsten/hafnium).

An electric arc is ignited between the electrode insert (cathode) and the nozzle (anode). The bushing is used for connecting current-carrying parts and serves as an insulator.

Air is supplied to the inner chamber of the nozzle under pressure. Once in the electric arc, the gas turns into plasma and is blown out by a new portion of air through the nozzle opening.

The nozzle is cooled by air flow. High-power plasma cutting tools use liquid cooling, which provides a better cutting quality.

The plasma jet melts the section of metal above which the plasmatron head is located. When it moves along the trajectory set by the program or operator, the melt is blown out by the airflow and a cut remains in the metal.

The plasma cutting tool can work with 30-800A current sources.

PRODUCT LINE

| POWERMAX 30XT

Сила тока – Сопло 30А – 4282431, 4282442 |

POWERMAX 65

Сила тока – Сопло 45 А – 220941, 220930 65 А – 220819, 220797

|

POWERMAX 85

Сила тока – Сопло 45 А – 220941, 220930 65 А – 220819, 220797 85 А – 220816, 220797 |

POWERMAX 125

Сила тока – Сопло 45 А – 420158, 420151 65 А – 420169 125 А – 220975 |

| HPR 130XD

Сила тока – Сопло 30А – 220193 50 А – 220554 80 А – 220188, 220806 130 А – 220182, 220646 |

HPR 260XD

Сила тока – Сопло 30А – 220193 50 А – 220554 80 А – 220188, 220806 130 А – 220182, 220646 200 А – 220354, 220659 260 А – 220439, 220542 |

HPR 400XD

Сила тока – Сопло 30А – 220193 50 А – 220554 80 А – 220188, 220806 130 А – 220182, 220646 200 А – 220354, 220659 260 А – 220439, 220542 400 А – 220632 |

HPR 800XD

Сила тока – Сопло 30А – 220193 50 А – 220554 80 А – 220188, 220806 130 А – 220182, 220646 200 А – 220354, 220659 260 А – 220439, 220542 400 А – 220632 600 А – 220709 800 А – 220882 |

| HSD 130

Сила тока – Сопло 45 А – 220525 50 А – 220530 130 А – 220489 |

MAXPRO 200

Сила тока – Сопло 50 А – 220890 130 А – 220892 200 А – 420044 |

SELECTION

In the request, please, specify the model of your plasma cutting equipment and operating modes. Our specialist will select the necessary nozzle and spare parts.