APPLICATION

Equipment for cold rolling of sheet metal into profiled products.

Profiled sheets are used in construction for enclosing structures (roofs, walls, doors, thermal insulation panels) and shaped elements. The metal profile is used for spanning buildings and structures. The product is used in prefabricated construction.

The roll forming machine is used for the production of:

- Metal tile

- Roofing sheets

- Profile sheets

- Corrugated sheets

The metal profile is made with the required rigidity and strength. Using a type of profile with a suitable cross-section helps to save on supporting structures and reduces metal consumption. The sheet has the necessary spaces for easy installation.

The material is 0.2-0.8mm steel. Standard width of sheets: 1000/1200/1220/1250mm. Product length: up to 12m. Galvanized or painted sheets are available.

FEATURES

The machine control system is fully automated and minimizes the human factor influence. The roll forming machine is controlled by a computer via a touch-screen graphical interface.

The tachometer monitors the unwound steel length and counts the produced profile length.

The shafts and passline rolls of the machine are manufactured on CNC machines with high precision.

Metal parts are made of structural steel with a chrome coating 0.05mm. The material of the shafts and rollers is wear and rust resistant. The guillotine blade is made of hardened steel and has a long service life.

The frame of the roll forming machine is annealed to prevent stresses and deformations during operation.

All roll forming machines are pre-tested before shipment. The equipment is guaranteed for 12 months.

We perform commissioning and provide technical support throughout the entire service life.

STRUCTURE AND OPERATION

The equipment pulls the steel sheet from the roll and feeds the web to the roll forming machine. The machine is a bending matrix equipped with rows of rollers on shafts driven by chain transmission.

The sheet is profiled as a result of bending, where the sheet is simultaneously exposed to compressive and tensile forces. Rows of rollers gradually form the sheet into the desired profile, pressing the metal to the matrix.

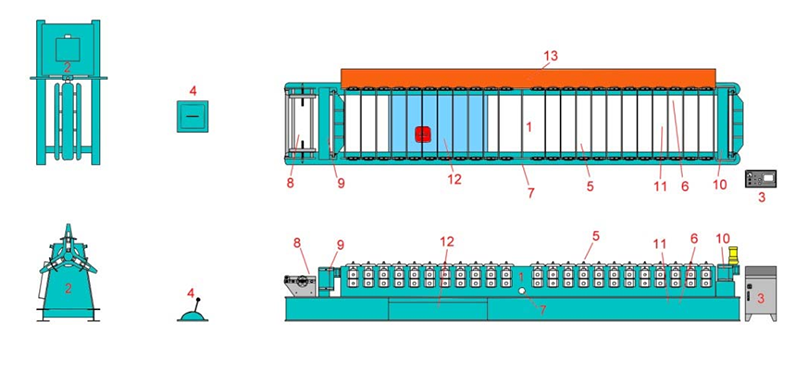

1 Roll forming machine

2 Uncoiler

3 Control unit

4 Decoiler sensor

5 Roller conveyor

6 Main motor

7 Hydraulic drive

8 Guide table

9 Front cutter

10 Rear cutter 11 Oil tank

12 Water tank

13 Transmission drive

At the machine exit, the profiled sheet is cut off with hydraulic shears and fed to the roller conveyor.

The rolling machine, electric and hydraulic drives, and chain transmission are assembled on a single frame. The uncoiler is a separate machine equipped with a sheet speed sensor.

OPTIONS

The equipment contains all units necessary for sheet metal bending. Additionally, the roll forming machine is equipped with mechanisms that form the production line:

- Decoiler

- Guillotine (electromechanical/hydraulic)

- Mechanisms for conveying finished products (roller conveyor)

- Packaging and marking equipment

SELECTION

To select the equipment suitable for the production of the required metal sheet please, leave a request to our specialist. Attach product drawings to the request and specify the required performance.