APPLICATION

The electric motor with split poles is used for assembling compact fans in refrigeration and heating units. The component is suitable for applications that do not require the creation of a large torque.

The fans based on such motors are suitable both for exhaust and delivery of the gaseous medium.

The component is used in the fans of:

- Refrigeration equipment

- Heat guns

- Air conditioning pumps

- Humidifiers

- Air purifiers

The electric motor is additionally equipped with an impeller, a protective grid, and a bracket. Please, refer to the table below to select a suction or discharge impeller.

FEATURES

Fans equipped with a split-pole motor are used for tasks that do not require the creation of a large torque.

The motor can withstand frequent starts and sudden stops. Allows long periods of downtime. In technical terms, corresponds to the long-term operation mode S1.

The electric motor is non-reversible. Clockwise or counterclockwise rotation.

Mounted in a horizontal position. The component is attached with the screws. The YZF-00 series motors do not have special mounting screws. The YZF-18/26 series motors have 2 pairs of mounting screws with fitting distances of 18 and 26 mm. The YZF-18 and YZF-26 series motors have 1 pair of mounting screws with a distance of 18 and 26 mm, respectively.

The YZF-18/26 series motors include the technical features of YZF-18 and YZF-26 series.

The micromotor has a low noise level

The permissible operating temperature is 0-60°C.

The motor has a simple design. No maintenance required.

STRUCTURE AND OPERATION

A split-pole motor is a single-phase asynchronous electric motor. It uses standard AC networks 220/380V.

The electric motor is manufactured with an external or internal rotor. The motor stator contains 2 windings located on opposite poles. The main winding is connected to the supply network. The auxiliary winding is shorted and has 1-3 turns per pole.

The motor rotor is short-circuited. Cooling fins are fixed at the rotor ends.

The main stator winding is positioned symmetrically or asymmetrically relative to the rotor. Asymmetric electric motors are characterized by significant magnetic flux scattering and efficiency not exceeding 15%. Symmetrical engines are technically more difficult to manufacture, but their efficiency reaches 25%.

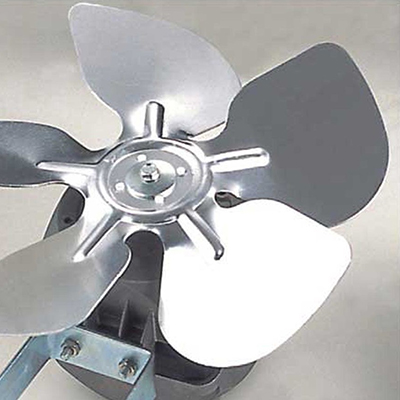

The fan consists of an electric motor and an impeller mounted on its axis.

The impeller is a metal or plastic blade mounted on the sleeve. The blades are positioned at an angle to the axis of rotation. The flow rate and pressure generated are determined by the area and angle of the blades, as well as the motor power.

Table for selection of the suction impeller

| Motor output power (W) | 3 | 5 | 7 | 10 | 16 | 18 | 20 | 25 | 34 | Impeller diameter (mm) | |||||||||

| Frequency (Hz) | 50 | 60 | 50 | 60 | 50 | 60 | 50 | 60 | 50 | 60 | 50 | 60 | 50 | 60 | 50 | 60 | 50 | 60 | |

| a°max | 31 | 31 | 34 | 34 | 154 | ||||||||||||||

| 28 | 28 | 31 | 31 | 34 | 34 | 172 | |||||||||||||

| 25 | 25 | 28 | 28 | 31 | 28 | 31 | 31 | 200 | |||||||||||

| 22 | 19 | 25 | 22 | 25 | 25 | 28 | 28 | 31 | 28 | 34 | 34 | 230 | |||||||

| 22 | 19 | 25 | 25 | 25 | 25 | 28 | 25 | 31 | 28 | 250 | |||||||||

| 19 | 19 | 19 | 19 | 21 | 21 | 23 | 23 | 25 | 25 | 300 | |||||||||

Table for the selection of discharging impeller

| Motor output power (W) | 3 | 5 | 7 | 10 | 16 | 18 | 20 | 25 | 34 | Impeller diameter (mm) | |||||||||

| Frequency (Hz) | 50 | 60 | 50 | 60 | 50 | 60 | 50 | 60 | 50 | 60 | 50 | 60 | 50 | 60 | 50 | 60 | 50 | 60 | |

| a°max | 28 | 28 | 31 | 31 | 154 | ||||||||||||||

| 25 | 25 | 28 | 28 | 31 | 31 | 172 | |||||||||||||

| 22 | 22 | 25 | 25 | 28 | 25 | 28 | 28 | 200 | |||||||||||

| 22 | 19 | 22 | 22 | 25 | 25 | 28 | 25 | 31 | 31 | 230 | |||||||||

| 19 | 19 | 22 | 22 | 22 | 22 | 22 | 22 | 28 | 25 | 250 | |||||||||

| 19 | 19 | 21 | 21 | 23 | 23 | 25 | 25 | 300 | |||||||||||

The fan can be equipped with a grid that protects the blades from foreign objects

PRODUCT LINE

| Voltage (V) | Current (A) | Input power (W) | Output power (W) | Speed (rpm) | A

(mm) |

B

(mm) |

С

(mm) |

D

(mm) |

E

(mm) |

H

(mm) |

|

| YJF3-00 | 220/240 | 0.16 | 20 | 3 | 1300/1550 | 79.5 | 15 | — | 31 | — | 12.5 |

| YJF5-00 | 220/240 | 0.20 | 30 | 5 | 1300/1550 | — | — | ||||

| YJF7-00 | 220/240 | 0.27 | 38 | 7 | 1300/1550 | 89.5 | 17.5 | — | 33.5 | — | 20 |

| YJF10-00 | 220/240 | 0.30 | 42 | 10 | 1300/1550 | — | — | ||||

| YJF12-00 | 400 | 0.18 | 40 | 12 | 1300 | 89.5 | 13 | — | — | — | 25 |

| YJF14-00 | 400 | 0.30 | 70 | 14 | 1300 | 95 | 18 | — | — | — | |

| YJF16-00 | 220/240 | 0.40 | 58 | 16 | 1300/1550 | 100.5 | 18.5 | — | 34.5 | — | |

| YJF18-00 | 220/240 | 0.43 | 64 | 18 | 1300/1550 | — | — | 30 | |||

| YJF20-00 | 220/240 | 0.47 | 65 | 20 | 1300/1550 | — | — | ||||

| YJF25-00 | 220/240 | 0.70 | 100 | 25 | 1300/1550 | 110.5 | 18.5 | — | — | 40 | |

| 400 | 0.48 | 115 | 25 | 1300 | 108.5 | 16.5 | — | — | — | ||

| YJF34-00 | 220/240 | 0.90 | 120 | 34 | 1300/1550 | 114.5 | 17.5 | — | 33.5 | — | 45 |

| YJF3-26 | 220/240 | 0.16 | 20 | 3 | 1300/1550 | 79.5 | 15 | 46 | 31 | — | 12.5 |

| YJF5-26 | 220/240 | 0.20 | 30 | 5 | 1300/1550 | — | |||||

| YJF7-26 | 220/240 | 0.27 | 38 | 7 | 1300/1550 | 89.5 | 17.5 | 48.5 | 33.5 | — | 20 |

| YJF10-26 | 220/240 | 0.30 | 42 | 10 | 1300/1550 | — | |||||

| YJF16-26 | 220/240 | 0.40 | 58 | 16 | 1300/1550 | 94.5 | 17.5 | 48.5 | 33.5 | — | 25 |

| YJF18-26 | 220/240 | 0.43 | 64 | 18 | 1300/1550 | 100.5 | 18.5 | 49.5 | 34.5 | 20 | 30 |

| YJF20-26 | 220/240 | 0.47 | 65 | 20 | 1300/1550 | ||||||

| YJF25-26 | 220/240 | 0.70 | 100 | 25 | 1300/1550 | 110.5 | 18.5 | 30 | 40 | ||

| YJF34-2G | 220/240 | 0.90 | 120 | 34 | 1300/1550 | 114.5 | 17.5 | 48.5 | 33.5 | 35 | 45 |

| YJF3-28/18 | 220/240 | 0.16 | 20 | 3 | 1300/1550 | 79.5 | 15 | 46 | 31 | — | 12.5 |

| YJF5-26/18 | 220/240 | 0.20 | 30 | 5 | 1300/1550 | — | |||||

| YJF7-28/18 | 220/240 | 0.27 | 38 | 7 | 1300/1550 | 89.5 | 17.5 | 48.5 | 33.5 | — | 20 |

| YJF10-26/18 | 220/240 | 0.30 | 42 | 10 | 1300/1550 | — | |||||

| YJF16-26/18 | 220/240 | 0.40 | 58 | 16 | 1300/1550 | 94.5 | 17.5 | 48.5 | 33.5 | — | 25 |

| YJF18-26/18 | 220/240 | 0.43 | 60 | 18 | 1300/1550 | 100.5 | 18.5 | 49.5 | 34.5 | 20 | 30 |

| YJF20-26/18 | 220/240 | 0.47 | 65 | 20 | 1300/1550 | ||||||

| YJF2S-26/18 | 220/240 | 0.70 | 100 | 25 | 1300/1550 | 110.5 | 30 | 40 | |||

| YJF34-26/18 | 220/240 | 0.90 | 120 | 34 | 1300/1550 | 114.5 | 17.5 | 48.5 | 33.5 | 35 | 45 |

| F154

154 |

F172

172 |

F200

200 |

F230

230 |

F250

250 |

F285

265 |

F300

300 |

F340

340 |

||

| 19° | в | 24 | 23 | 26 | 30 | 31 | 33 | 36 | 42.5 |

| c | 13 | 11 | 12.5 | 14.5 | 15 | 16 | 18 | 21 | |

| 22° | в | 27 | 26 | 30 | 35 | 35 | 38 | 41 | 49 |

| c | 14 | 13 | 14.5 | 16 | 17 | 19 | 20 | 24 | |

| 25° | в | 31 | 30 | 34 | 39 | 40 | 43 | 46.5 | 55.5 |

| c | 16 | 15 | 16.5 | 19 | 19.5 | 21 | 23 | 28 | |

| 28° | в | 34 | 33 | 37.5 | 42 | 44 | 48 | 52 | 61 |

| c | 17 | 16 | 18 | 20.5 | 21.5 | 24 | 25 | 30 | |

| 31° | в | 37 | 36 | 41 | 47 | 48 | 52.5 | 57 | 67 |

| c | 19 | 17 | 20 | 23 | 23.5 | 26 | 28 | 33 | |

| 34° | в | 40 | 39 | 44 | 51 | 53 | 57 | 62 | 73 |

| c | 21 | 19 | 22 | 25 | 26 | 28 | 30 | 36 | |

SELECTION

To select a suitable fan model, please, leave a request to our specialist. In the request, describe the task that you need to solve.