APPLICATION

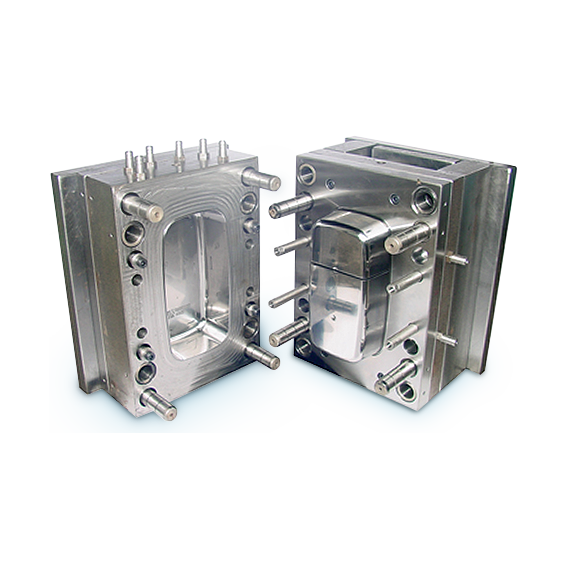

The mold is used for injection molding of bulky plastic products. It defines the shape, construction, and texture of the product.

The mold is used in injection molding machines. Suitable for various plastics: ABS, PVC, PET, polypropylene, polyethylene, polystyrene, polycarbonate, polyamide.

Molds are used for the production of:

- Household products: buckets, dishes, containers, clothespins

- Plastic furniture: tables, chairs, stools

- Automobile components: bumpers, dashboards, interior elements, lighting equipment

- Housings of household and industrial appliances

- Containers and packages: boxes, containers, vials, caps, lids, pallets

- PET products: bottles

- Medical devices: test tubes, droppers

- Labware: Petri dishes, test tubes

- Toys

- Stationery

- Fittings for engineering communications: water and gas supply, sewerage

Molds are used in mass production. Usually, it is necessary to produce 300-500 pieces of one product to pay for the mold. The larger the production volume and the mold resource, the more profitable its use.

The injection molding machine is equipped with at least one mold. The number of forms used depends on the required range and production plan of the enterprise. On average, 1 casting machine uses 2-5 molds.

FEATURES

The mold manufacture quality determines the accuracy of the product shape matching the drawing, the working life, the casting cycle time, and the waste amount. These parameters affect the injection molding machine performance and the production cost.

The molds are made of stainless steel.

Casting molds can be:

- Single-piece

- Multi-piece (several products in one mold)

Single-piece molds are convenient for small productions and for the production of a narrow range of products. Their cost is lower than that of multi-piece mold. With a multi-piece mold, efficiency increases significantly. First, several articles are produced at once in one cycle. Second, the mold cooling time is reduced: it takes up to 50% of the total time in each cycle. In addition, products of various geometries can be cast in a multi-piece mold in one cycle. Multi-piece molds are usually used for mass production.

By the automation degree, there are:

- Manual (the product is removed manually)

- Semi-automatic (the product is removed without the operator)

- Automatic (the product is removed and the gate is sheared without the operator)

- Robotic (the operator only sets the program)

By the design, the molds can be stationary, removable, and semi-removable. The jointing plane can be located in a horizontal or vertical plane. Sometimes, molds are made with multiple jointing planes.

The molds are attached to the casting machine using bolts or electromagnetic plates. Using electromagnetic plates reduces the mold changeover time. In addition, this fastening is characterized by a uniform force over the jointing plane, there are no fast-wearing holes of bolted connections in such molds.

The mold gating system can be cold or heated. The cold-channel design is easy to manufacture but has significant disadvantages. First, the increased material consumption and the need to manually separate the gate from the product. Secondly, the cooling time is longer, since the gate cools down longer than the product itself. Hot-channel molds do not have such disadvantages, but they are technically more complex and more expensive.

The mold design is developed according to the product drawings. 3D modeling and computer simulation of the casting process (mold flow) are used in the designing. When developing a model, shrinkage is taken into account and the necessary inclines and tolerances are set.

The molds are manufactured in China on CNC machines. Quality is monitored using profile meters equipped with optical sensors. The precision of mold manufacturing reaches 0.1µm. Before shipping, the finished mold is installed in the injection molding machine and tested.

STRUCTURE AND OPERATION

The mold consists of a forming unit, guide elements, a gating system, a thermal control system, and an ejection system.

The forming unit includes a fixed part (matrix) and a movable part (punch). The punch presses on the raw material during pouring, ensuring the filling uniformity. The closing force depends on the version of the injection molding machine and reaches 10-100tons. The mold cavities form a negative impression of the external surface of the future product.

The material is fed to the mold under pressure through a gating system – central, spreading, and inlet gates.

Heating/cooling systems are used to maintain the required temperature and cooling conditions after pouring into the mold. Tubular heating elements are used for heating, and a water circuit is used for cooling.

The ejection system removes the finished product from the mold after cooling.

Usually, a mold consists of standard external modules and internal elements that define the product geometry. Internal elements are made on order. Standard modules are purchased from major manufacturers and can be easily replaced if necessary.

PRODUCT LINE

SELECTION

To calculate the cost of the mold, please, leave a request. Attach product drawings or a sketch. Specify the model of the injection molding machine used, the type of plastic, the required performance, and the automation degree